Research and Development

Pioneers in the plant room - a Cattani success story

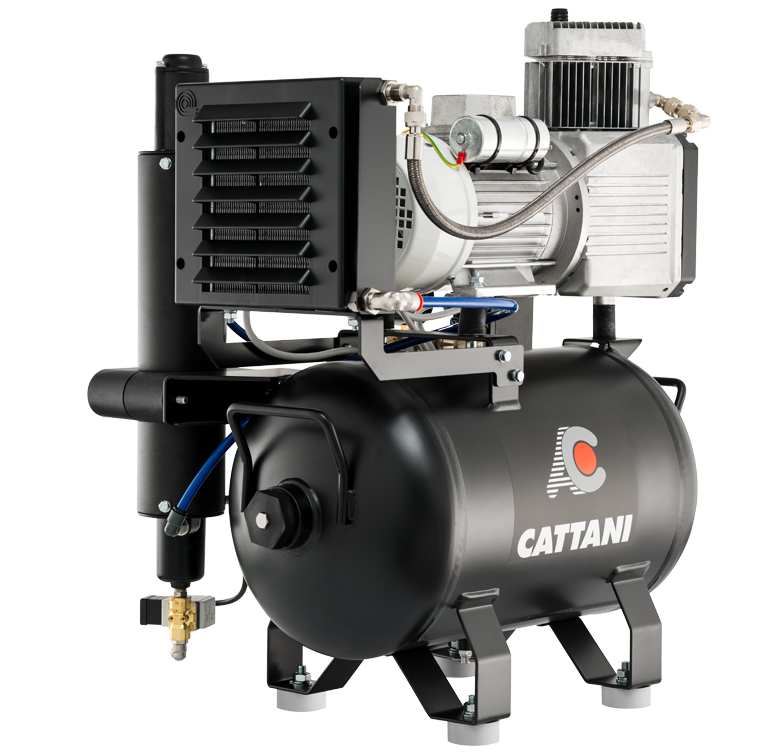

For more than 50 years, Cattani dental air technology has been synonymous with unparalleled quality, performance and service. The company has always focused on two main product areas – suction and compressors – so there have been no distractions in our aim to be world leaders in our field.

R&D

Firm foundations

Since its establishment in 1967, Cattani has placed primary importance on imagination and research in design, and an insistence on the quality of its aspiration and compressed air distribution systems. On these foundations, Cattani has built a reputation for innovation and excellence. This has been enhanced by a focus on environmentally-friendly use of raw materials and efforts to reduce energy consumption, which has been embraced by the marketplace, with Cattani products sold globally.

R&D

How we lead

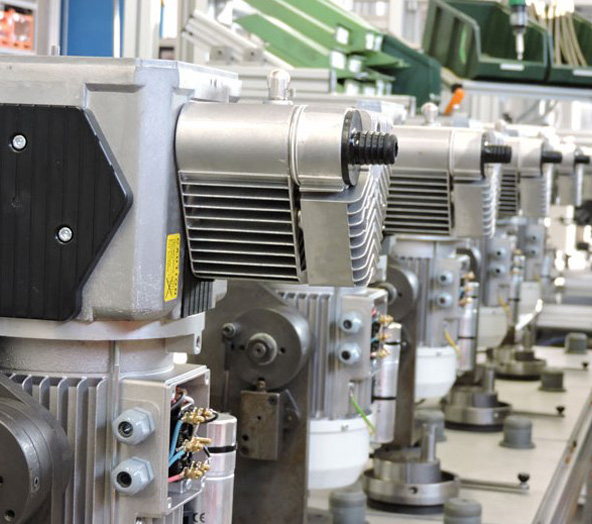

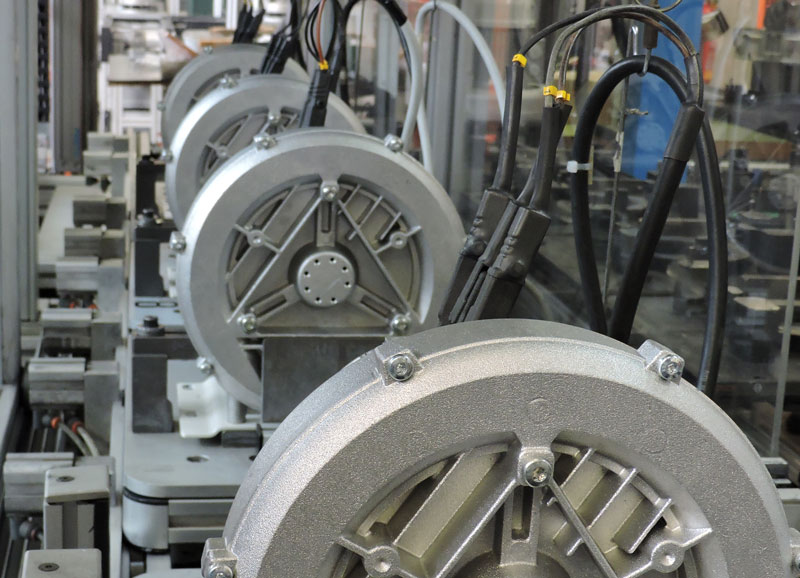

Constant research: this enables us to apply the latest technology to all of our products and solutions.

We enhance performance: electronic and information technology enables us to enhance the performance and reliability of our products.

We reduce costs: less maintenance and lower energy costs mean that we are always the most economical on a cost-benefit analysis.

We reduce environmental impact: we save 50% on raw materials, and allow you to save between 30% and 50% on electrical consumption.

R&D

Inverter technology - Cattani did it

Cattani innovation through research and development is best illustrated by its industry-leading work with inverter technology, implementing ideas that were years ahead of their time. Traditional dental suction motors have a fixed speed that makes them notoriously inefficient. Mr Ennio Cattani, head of the Cattani company in Italy, son of founder Dr Augusto Cattani and a hands-on engineer himself, pioneered the use of inverter technology in dental suction equipment, solving this waste energy problem to the added benefit of the dentist’s bottom line.

FUN FACT

Out of this world

Cattani capability and innovation was acknowledged in a special and memorable way when Ferrari Engineering, as supplier to the European Space Agency, commissioned Cattani and its sister company ESAM to supply the air technology for the NASA space shuttle. Our Italian engineers designed and built a tiny 180gm compressor able to maintain a pressure of 38 bar for the purpose. We were over the moon with its performance. Cattani and ESAM also contributed to the Eurostar project – the pride of the Italian railway system, producing the train’s pressurisation system.