Oil-Free Dental Air – For Successful Composite Bonding

Compressed air plays a major role in modern dentistry, despite often being the unsung hero. It is used to purify air quality, remove bacteria, and power many of a dentist’s tools. From a prophylaxis handpiece to CAD/CAM dental milling machines, dental compressed air is also used inside the mouths of patients, therefore requiring the utmost hygiene quality.

Moisture, blood, and oil can act as potential contaminants of tooth surfaces that may lead to composite bonding failure. During the enamel preparation process, the presence of oil in the air or water syringes from air compressors could create a potential source of contamination coating the enamel surface. This can often lead to unexpected results during dental treatment.

Composite dislodgement

Some composites are more prone to dislodging than others, such as Class V composites, where mechanical retention is not used to provide additional stability and strength to the composite restoration. When such dislodgement occurs, there are a few common causes.

- Bonding agent – The adhesives have inadequate bonding strengths that weaken over time.

- Light cure unit (LCU) – This equipment may have decreased light output, either because of electricity fluctuations or defects in the bulb or light rod. This reduces its effectiveness of the bond.

- Triple syringe - Air from the triple syringe may also be contaminated with moisture and/or oil from the compressor.

Oil contamination from the compressor

The possibility of oil contamination from the compressor is generally considered very late during trouble shooting, or completely missed. This is because dental plant equipment, namely the dental compressor, is usually out of sight, out of mind to the end user. The use of oil-free compressors will prevent oil contamination to provide continuous and pure compressed air in line with ISO22052:2020.

Understanding ISO22052:2020

To understand the importance of oil-free air in dentistry it is critical to understand ISO 22052:2020 which is the international standard the defines dentistry plant area equipment: compressor systems. There are four ways in which we define air quality. Each is important to providing high-quality air to dental treatment rooms.

The ISO 22052:2020 defines standards for dentistry plant area equipment: Compressor Systems. Within this standard it references ISO8573-1 which defines that dental air produced by the dental compressor shall conform to purity class 2:4:2.

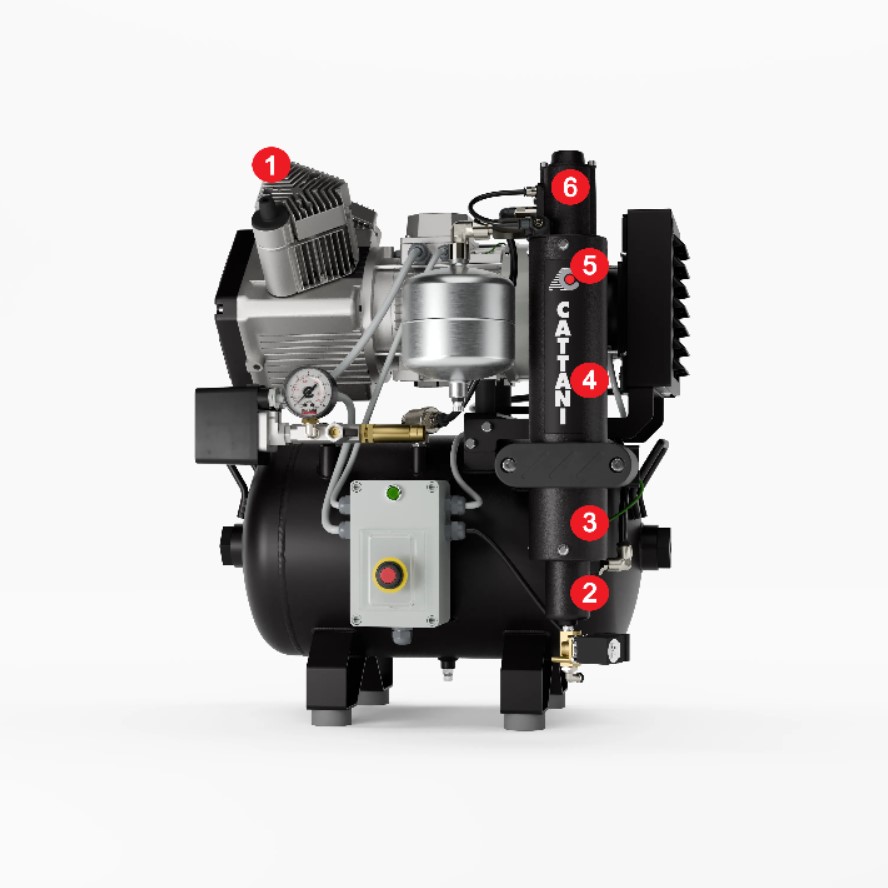

Particle Class 2: Number of particles in the air with a size between 1µm and 5µm in dental air is ≤ 100/m3. Cattani compressors exceed this Class 2 requirement and satisfy Class 1 for solid particulate, thanks to the HEPA H14 filter on top of the drying column. The bacterial filter removes 99.975% of 0.3 micron or larger particles.

Humidity Class 4: Cattani compressors meet this standard using a drying system. Air output is a constant humidity level that will not condense fluid in the oral cavity. Cattani also offers an optional pre-filter accessory to cater to humid environments.

Oil Content Class 2: Oil content of the dental air is ≤ 0.1 mg/m3. Cattani compressors do not rely on oil for lubrication of moving parts. They do not contain any oil in the piston and cylinder assemblies which can affect air quality.

Dental air compressors that meet or exceed this international standard go a long way towards the success of composite bonding.

Oil-free dental compressors for composite bonding

Regardless of the number of layers in a filtration system, there is but one satisfactory outcome in this scenario – successful composite bonding. This can be accomplished with the help of oil-free compressed air delivered through a multilayer antibacterial filtration system.

Quality and precision are what we pride ourselves in after more than 50 years of specialising in premium air technology. Our antibacterial HEPA H14 filter (High-Efficiency Particulate Air), comes standard with all dental compressors and helps deliver quality results by removing 99.975% of solid and biological particles down to 0.3 micron.

The process to deliver hygienic, clean, dry dental air is imperative to the ongoing success of dental clinics.

With our commitment to the highest level of air quality, Cattani oil-free dental air compressors deliver clean, dry, and hygienic air, with the reliable performance to keep your practice and laboratory running.

Click below to learn more about Cattani’s Six-Stage Dental Air Purification System.

Alternatively, call us on +65 6708 7434

OTHER STORIES

Cattani News

Cattani Group Welcomes Nigel Blaydes as Regional Commercial Manager – Asia

…Read More →

Cattani News

Cattani Asia at MDA SCATE 2025: A Strong Start to the Year

…Read More →

Cattani News

When Breakdown Is Not an Option: Cattani Asia Supporting Critical Facilities

…Read More →

Cattani News

Cattani Asia’s Expanding Reach: Partner Support Shines at MIDEC 2024 and VIDEC 2024

…Read More →